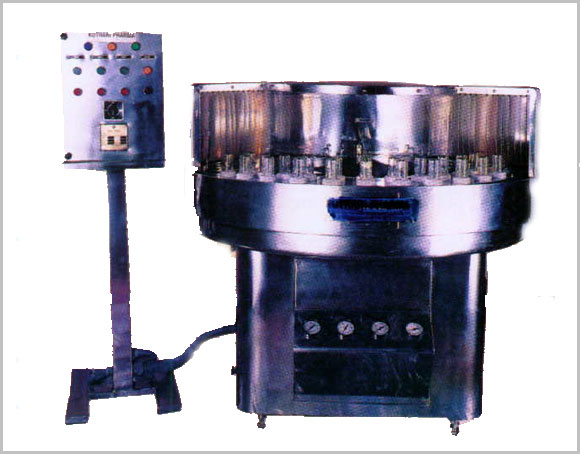

Rotery Bottle Washing Machine

Liquid/ Dairy section | Beverage & Winery machine

Rotery Bottle Washing Machine

Vitro Pharma Machine provides Rotary Bottle Washing Machine which is a compact and highly efficient machine with an elegant look. This multi-functional multi-featured Rotary Bottle Washing Machine machine meets the GMP requirements of washing for glass and plastic bottles.

Rotary Bottle Washing Machine operates on its Rotary principle with "GENEVA" mechanism and requires manual loading and unloading of bottles.

- Geneva mechanism.

- Four inners and one outer wash.

- The sequence of washes to customer's choice.

- Suitable to wash 5ml to 500ml bottles.

- Variable speed drive for output between 64 & 100 bottles per minute.

- Easy to operate.

- Stationary nozzles eliminate contamination of water cycles.

- Easy loading and unloading with two rows.

- Meets GMP and FDA norms.

- Individual solenoid valve for each washing sequence which eliminates carbon plate and other accessories reduces leakage and maintenance to a minimum.

- Higher capability centrifugal pumps to scrub larger bottles (500 & 1000 ml.)

- Pumps and tanks are mounted on a portable stand for easy maintenance.

The bottles are loaded on a rotating platform and are cleaned in a series of operations. The bottle holds in bottle holders which are specially designed to accommodate bottles with varying neck diameter and bottle diameter and placed in an inverted position in these cup-shaped holders. The outside cleaning of the bottles is done by spraying showers. Solenoid valves are provided to enable the regulation of wash timings and sequence of various washing media to suit a specific requirement.

TECHNICAL DETAILS |

SCOPE OF SUPPLY |

|

| Max. dia. of bottle | 85 mm. | 1) S.S. tanks capacity 75 lts. (2 nos.). |

| Output / minute | 100 bottles | |

| No. of pumps | 2 | 2) Centrifugal pump with T.C. v/s T.C. seal. |

| Type of pumps | Centrifugal (3/4") | |

| Motor | 1 HP/3000 RPM/440V | 3) 4 nos. solenoid valves and 4 nos. manual valves |

| S.S. tanks | 2 nos. 75 litres each | |

| main drive | 1 HP / 3 phase | 4) 64 nos. specially designed bottle holders. |

| Electrical load | 5 KW | |

| Overall dimm.(mm) | 1700Lx1900Wx1300 H | 5) Stand mounted panel board. |

| Net weight | 650 Kg. | |

| Gross weight | 1050 Kg. | |

- Individual solenoid valve for each washing sequence which eliminates carbon plate and other accessories reduces leakage and maintenance to minimum.

- Variable speed drive for out put between 64 & 100 bottles per minute.

- Higher capacity centrifugal pumps to wash bigger bottles (500 & 1000 ml.).

- The stationary nozzles avoid chipping of bottle necks.

- Pumps and tanks are mounted on portable stand for easy maintenance.